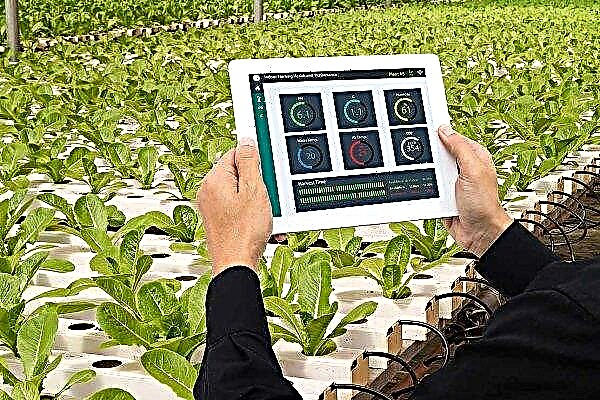

Entrepreneurs and researchers gathered at InovaPork in Brazil to present innovative alternatives in the areas of efficiency, sustainability and profitability of pig production.

InovaPork, organized by Embrapa, a Brazilian agricultural research corporation, has invited researchers to submit ideas.

Topics included artificial intelligence for diagnosing pig diseases, farm, environment and production environment management software, biogas filters, grease thickness scanners, and sensors to monitor water flow and feed efficiency.

The three winning presentations were devoted to “green” methods for cleaning residual water, reducing animal stress during transportation, and high precision artificial insemination.

Kemia won after it presented its solution to solve the problem of residual water treatment in small rooms inside pig farms. Currently, due to the fact that the cleaning systems require enough space, the plants are located far from the farm, which leads to increased costs and increased energy consumption. Its “green” methods save up to 30% of energy and reduce 90% of the area needed for efficient treatment plants.

In second place was a monitoring system used inside trucks to analyze critical factors related to animal stress levels. The goal was to identify factors that caused animal suffering or death, to improve and certify animal welfare and avoid loss.

In third place is B.Tool, which introduced a novelty in the field of precision artificial insemination in the Brazilian pig sector. Now it takes about 1.8 billion good cells to reach an effective fertilization rate, but with this new solution, manufacturers need only 0.8 billion cells.